The products

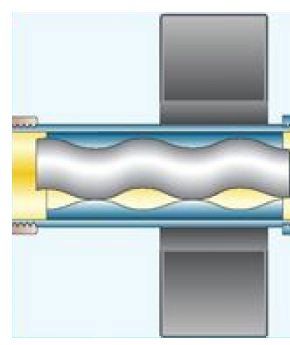

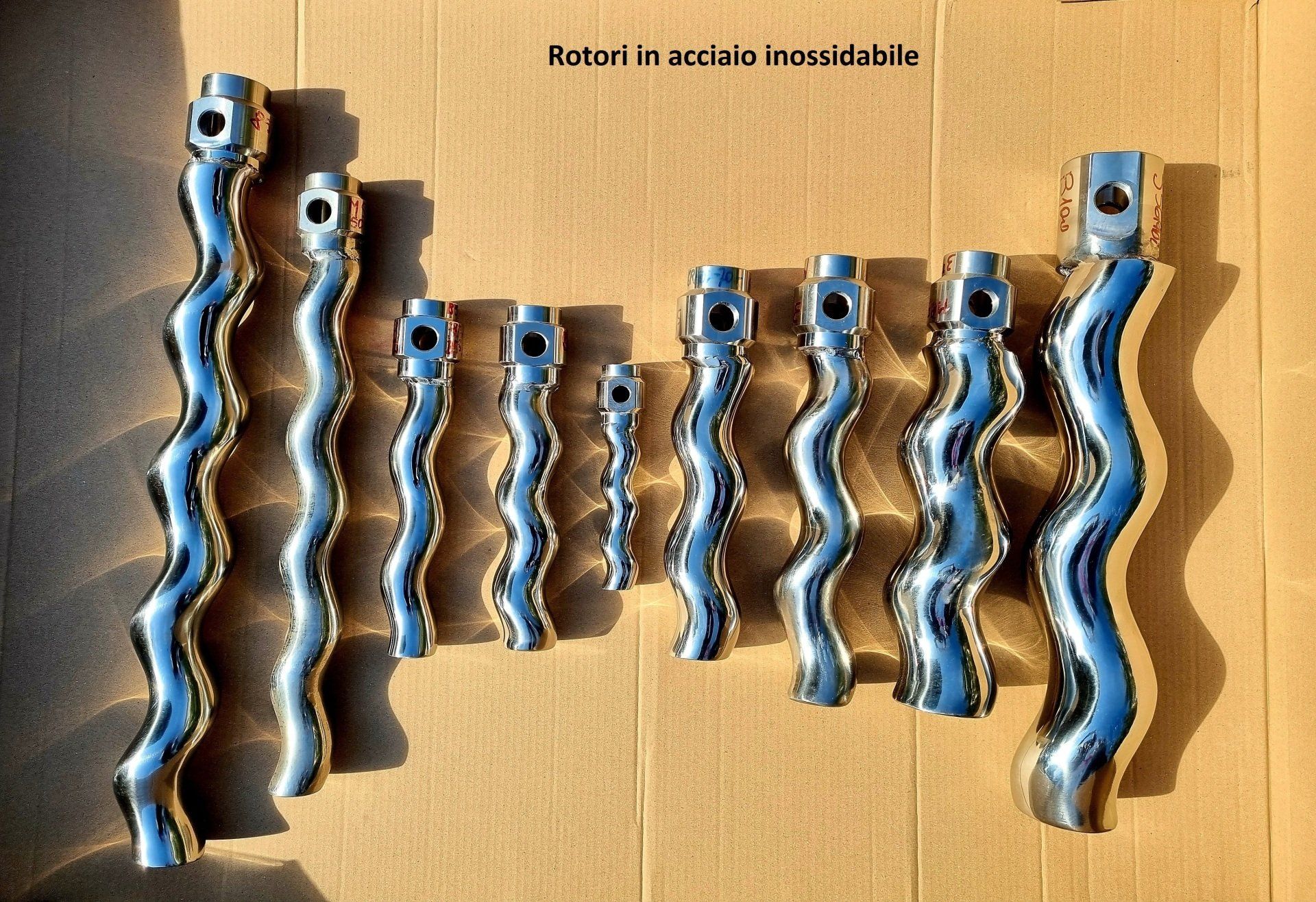

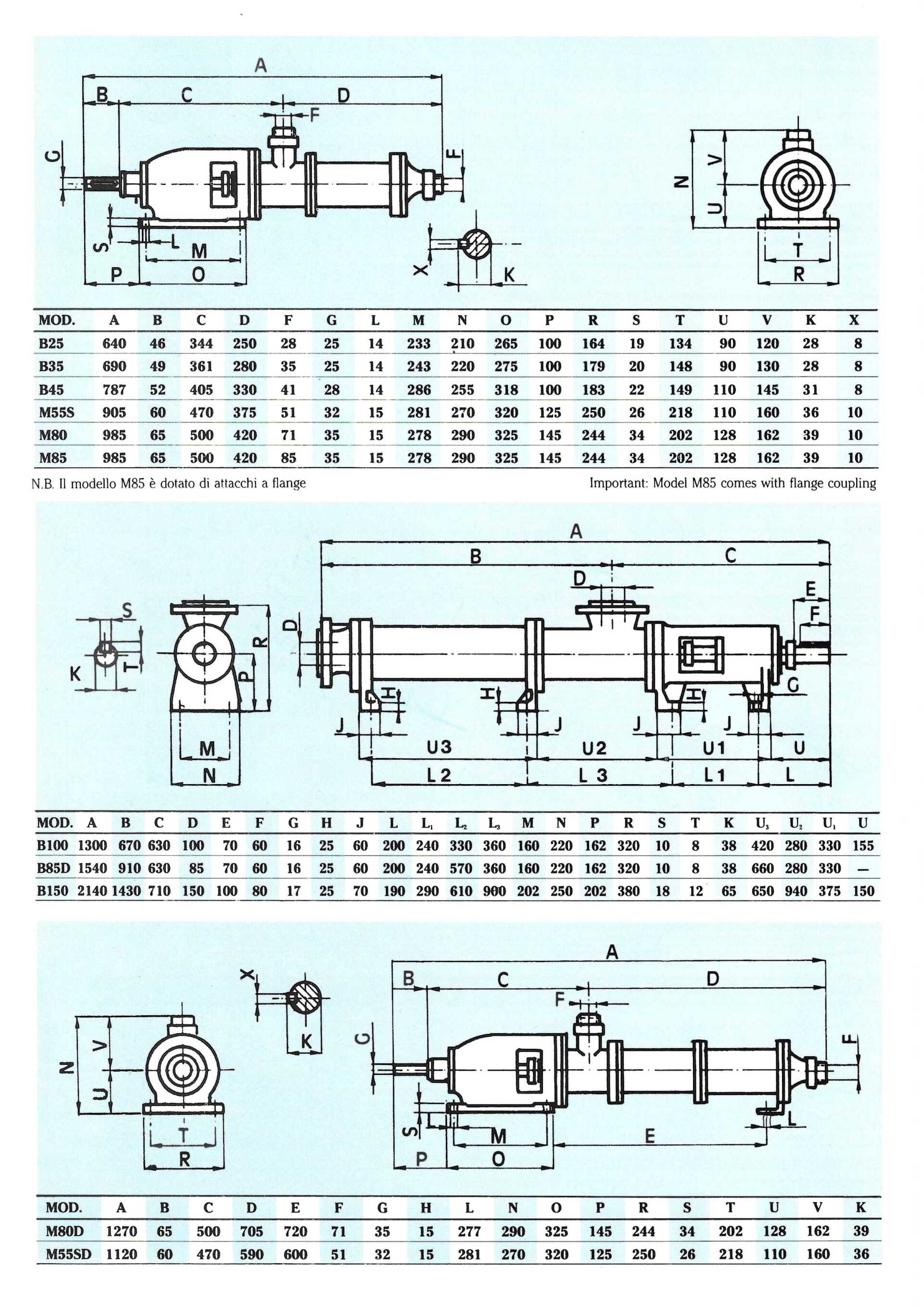

The Del Monte company produces helical screw pumps (single screw)They consist of a helical stainless steel rotor, possibly chrome-plated, rotating inside a fixed stator made of rubber or other material chosen based on the chemical-physical characteristics of the product and its temperature. The close contact between the rotor and stator allows for the regular and uniform movement of the liquid.

Advantages:

- transport of the fluid without shaking (turbulence phenomena, foam formation and oxidative processes are avoided)

- possibility of reversing the direction of rotation to reverse the flow of the liquid

- flow rate almost constant as the pressure varies

- self-priming with suction up to 7-8 metres

- robust construction and tight construction gaps

- Quick and easy disassembly and assembly of the pump (no specialized personnel required)

- significantly reduced driving power - at the same flow rate and head compared to other pumps of different design

- minimal maintenance, low operating costs, long life

Fields of application

Del Monte pumps are suitable for transporting a vast range of liquids, from fluids to very dense and viscous ones.

Any product that still has flow capacity, however reduced, can be pumped, even in the presence of suspended solids without damaging them.

Thanks to their exceptional flexibility of use, Del Monte pumps find optimal application in the most diverse sectors of the food industry (canning, winemaking, etc.), chemical, pharmaceutical, petrochemical, papermaking and in wastewater purification plants.

Helical screw pump with hopper and feed screw: (models M55SC,M80C,M80DC, B85C, M85C, B85DC, B100C)